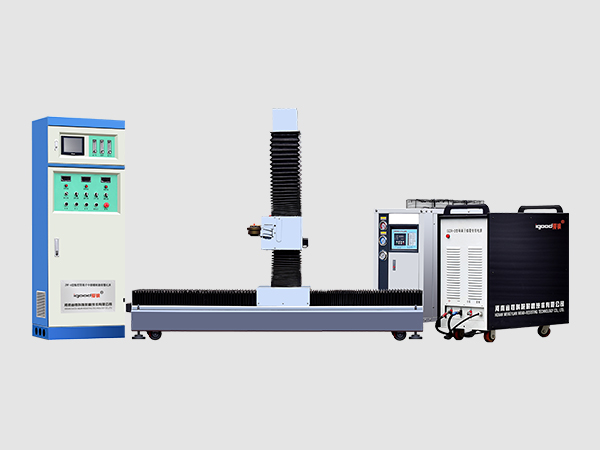

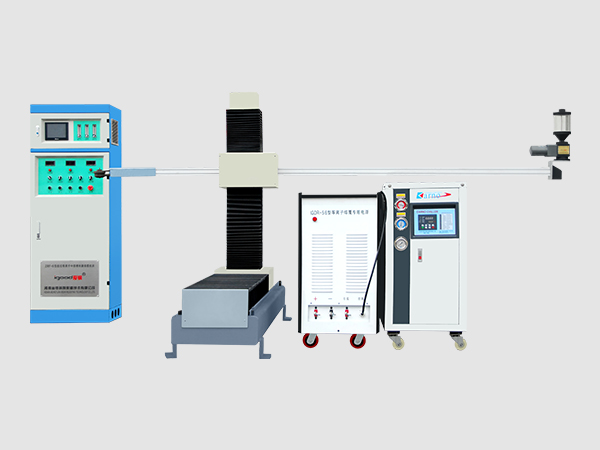

- Plasma welding machine

- Henan Igood is a modern company engaged in designing and manufacturing plasma welding machine, which has many benifits: high production efficiency.

The machine that can resolve the wear issues of scraper conveyor was successfully produced after repeated experiment. The strengthened layer and base material will be metallurgically combined in depth, which greatly enhances the wear and impact resistance of metal surface. It is verified by many years’ uses in underground coal mines that the strengthened central through by cladding is prolonged 2-3 times in service life averagely.

Composition:

Plasma power supply (cladding and arc striking)

CNC system

Precision powder feeder

Third generation plasma torch

cooling system

operation platform

servo-actuator

Application:

1.Repair and strengthen various types of scraper conveyor.

2.Repair and strengthen the chute of scraper conveyor.

3.Manufacturing wear-resisting, anti-corrosion, high temperatures resistant clad sheet steel for special purposes.

Technical Parameters:

|

Dynamic voltage |

380V |

cooling water flow rate |

10~16 L/min |

|

Control voltage |

220/24V |

cladding speed |

0~600mm/min |

|

Input power |

24kVA |

cladding layer thickness |

1~5mm |

|

Pilot arc current |

40~60A |

Cladding hardness |

HRC60~70 |

|

Cladding current |

100~300A |

Single cladding width |

60mm |

|

Plasma gas flow rate |

16L/min |

Workpiece size |

for all the middle grooves |

|

Feed air flow |

10 L/min |

Total weight |

About 2t |

Reliable performance

The degree of numerical control is high

Easy to use

Ideal beam quality and good welding quality